How to optimize the cutting speed and feed rate of a stainless steel saw blade?

Optimizing the cutting speed and feed rate of a stainless steel saw blade is crucial for achieving efficient, precise, and cost - effective cutting operations. As a stainless steel saw blade supplier, I have witnessed firsthand the impact of these parameters on the overall performance of the cutting process. In this blog, I will share some insights on how to optimize the cutting speed and feed rate for stainless steel saw blades.

Understanding the Basics of Cutting Speed and Feed Rate

Before delving into the optimization process, it is essential to understand what cutting speed and feed rate mean. Cutting speed refers to the speed at which the saw blade's teeth move relative to the workpiece. It is usually measured in surface feet per minute (SFM) or meters per minute (m/min). Feed rate, on the other hand, is the rate at which the workpiece is fed into the saw blade and is typically measured in inches per tooth (IPT) or millimeters per tooth (mm/tooth).

Factors Affecting Cutting Speed and Feed Rate

Several factors influence the optimal cutting speed and feed rate for a stainless steel saw blade.

Workpiece Material

Stainless steel comes in various grades, each with different hardness, ductility, and machinability. For example, austenitic stainless steels are relatively soft and ductile, while martensitic stainless steels are harder. Harder grades of stainless steel generally require lower cutting speeds to prevent excessive wear on the saw blade teeth.

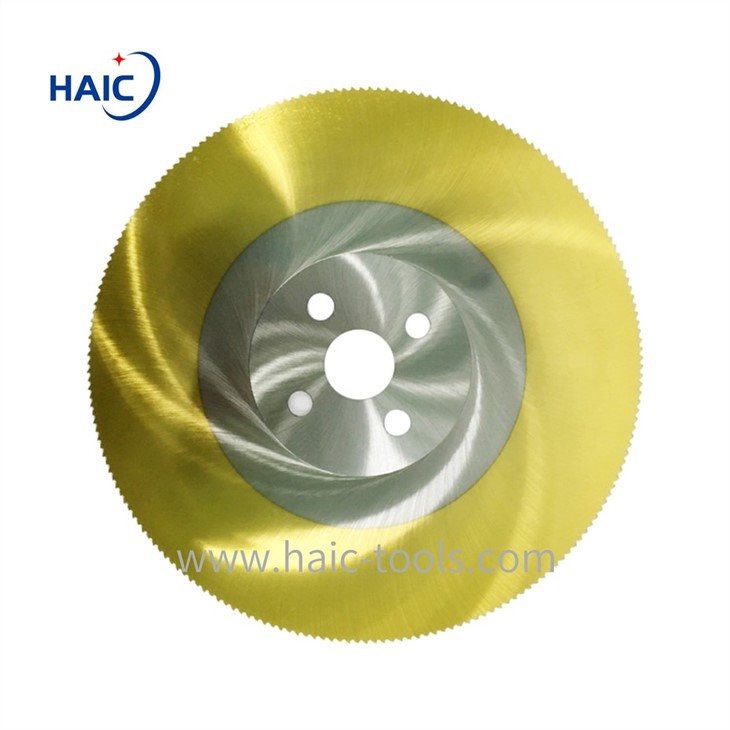

Saw Blade Type

Different types of saw blades have different capabilities. For instance, HSS Circular Saw Blade is made of high - speed steel and is suitable for a wide range of cutting applications. Orbital Blade has a unique design that can provide smooth and efficient cutting. Saw Blade for Aluminium Sash is specifically designed for cutting aluminium but may also be used for some softer stainless steel applications. The design, tooth geometry, and material of the saw blade play a significant role in determining the appropriate cutting speed and feed rate.

Machine Capabilities

The power, torque, and rigidity of the cutting machine also affect the cutting speed and feed rate. A more powerful and rigid machine can handle higher cutting speeds and feed rates compared to a less powerful one.

Optimizing Cutting Speed

To optimize the cutting speed of a stainless steel saw blade, the following steps can be taken:

Consult the Manufacturer's Recommendations

Saw blade manufacturers usually provide guidelines on the recommended cutting speeds for different types of saw blades and workpiece materials. These recommendations are based on extensive testing and research, so it is a good starting point.

Conduct Test Cuts

If possible, conduct test cuts on a sample workpiece. Start with a relatively low cutting speed and gradually increase it while monitoring the cutting performance. Look for signs such as excessive noise, vibration, poor surface finish, or rapid blade wear. The optimal cutting speed is the one that provides a smooth cut with minimal blade wear and a good surface finish.

Consider the Tool Life

Higher cutting speeds generally result in faster cutting, but they also increase the wear on the saw blade. Therefore, it is necessary to balance the cutting speed to achieve an acceptable tool life. If the saw blade wears out too quickly, it will increase the cost of production due to frequent blade replacements.

Optimizing Feed Rate

Optimizing the feed rate is equally important as the cutting speed. Here are some ways to optimize the feed rate:

Match the Feed Rate to the Cutting Speed

The feed rate should be proportional to the cutting speed. A general rule of thumb is that as the cutting speed increases, the feed rate can also be increased slightly, but not too much to avoid overloading the saw blade.

Account for the Tooth Geometry

The tooth geometry of the saw blade affects the chip load. A saw blade with larger teeth can handle a higher feed rate compared to one with smaller teeth. Make sure the feed rate is set in a way that the chips produced during cutting are of an appropriate size and can be easily removed from the cutting area.

Monitor the Cutting Force

During the cutting process, monitor the cutting force. If the cutting force is too high, it may indicate that the feed rate is too high, which can lead to blade breakage or poor cutting quality. Adjust the feed rate accordingly to maintain a stable cutting force.

Importance of Coolant and Lubrication

Using coolant and lubrication is essential when cutting stainless steel. Coolant helps to dissipate heat generated during cutting, which can reduce the risk of blade wear and improve the surface finish of the workpiece. Lubrication reduces friction between the saw blade and the workpiece, making the cutting process smoother and more efficient.

There are different types of coolants and lubricants available, such as water - based coolants and oil - based lubricants. The choice of coolant or lubricant depends on the specific cutting application and the requirements of the workpiece.

Case Studies

Let's take a look at some real - world examples to illustrate the importance of optimizing cutting speed and feed rate.

Case 1: A Metal Fabrication Shop

A metal fabrication shop was using a stainless steel saw blade to cut austenitic stainless steel sheets. Initially, they were using a high cutting speed and a low feed rate, which resulted in poor surface finish and rapid blade wear. After consulting with us, they adjusted the cutting speed to a more appropriate level and increased the feed rate. As a result, the cutting time was reduced by 30%, and the blade life was extended by 40%.

Case 2: A Precision Machining Company

A precision machining company was cutting martensitic stainless steel shafts. They were experiencing excessive vibration and poor dimensional accuracy due to incorrect cutting speed and feed rate settings. By following our recommendations and conducting test cuts, they were able to optimize the cutting parameters. This led to a significant improvement in the surface finish and dimensional accuracy of the shafts, reducing the rejection rate from 15% to 2%.

Conclusion

Optimizing the cutting speed and feed rate of a stainless steel saw blade is a complex process that requires considering multiple factors such as workpiece material, saw blade type, and machine capabilities. By following the steps outlined above, including consulting the manufacturer's recommendations, conducting test cuts, and using appropriate coolant and lubrication, it is possible to achieve efficient, precise, and cost - effective cutting operations.

If you are in the market for high - quality stainless steel saw blades or need further advice on optimizing cutting parameters, I encourage you to reach out to us. We are committed to providing you with the best solutions for your cutting needs.

References

- ASM Handbook Volume 16: Machining. ASM International.

- Kalpakjian, S., & Schmid, S. R. (2010). Manufacturing Engineering and Technology. Pearson.

- Trent, E. M., & Wright, P. K. (2000). Metal Cutting. Butterworth - Heinemann.