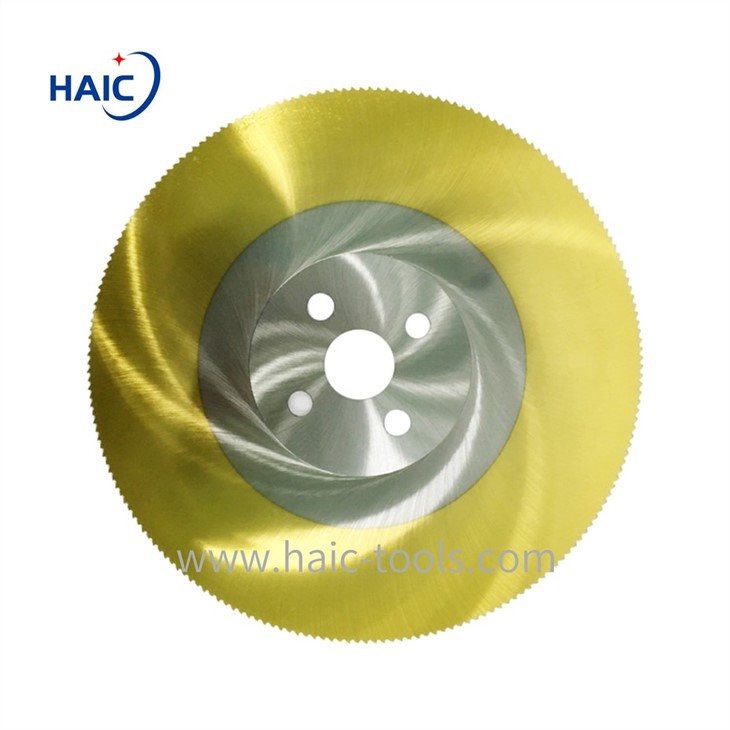

HSS Circular Saw Blade

HSS circular saw blade is widely used for cutting of various metal materials, especially steel pipes, sheets and profiles of thin wall. With more than 20 years’ technology, production know-how, and advanced production equipment, including NACHI vacuum heat treatment, PVD coating, and a range of advanced equipment and instruments for precision inspection. we can provide high quality HSS circular saw blades with different coatings to meet the cutting needs of various materials.

Product Introduction

Dear valued merchants,

We are excited to introduce our high-quality HSS circular saw blades to you. As a leading manufacturer located in China, we have been dedicated to providing our clients with the most innovative and reliable products to help them achieve remarkable growth.

With more than a decade of experience, we have continuously refined our production process for circular saw blades to meet the most demanding requirements of our clients. We use only premium quality raw materials to manufacture our blades, including high-speed steel and tungsten carbide-tipped teeth, ensuring they can deliver exceptional performance and longevity.

Our HSS circular saw blades are designed to cut through various materials, including mild steel and non-ferrous metals, without any difficulty. They are ideal for any application in which you need clean cuts, precision, and speed, making them an excellent choice for window or door fabrication, automotive parts manufacturing, and sheet metal processing.

Our HSS circular saw blades come in a vast range of diameters, from 200mm to 1000mm, and varying thicknesses. We offer different tooth geometries, such as ATB and TCG, to cater to different cutting applications. No matter what materials you need to work with, we have the right saw blade to help you achieve maximum productivity.

One of the key features of our HSS circular saw blades is their durability. They are made with tough, heavy-duty materials that can resist intense wear and tear, ensuring they can withstand the demands of a wide range of cutting applications. Our HSS circular saw blades are also easy to operate, thanks to their user-friendly design. They are designed to be compatible with most circular saw machines, so any operator with basic skills can use them efficiently.

Additionally, our HSS circular saw blades also offer a high level of precision, making them perfect for applications that require accuracy and consistency. They produce straight, smooth cuts, which reduces the need for rework, saves time, and reduces your overall costs.

At our factory, we have implemented strict quality control procedures to ensure that every HSS circular saw blade we manufacture reaches the highest standards. Before we ship our products to you, we conduct vigorous tests to ensure that each blade meets your requirements and exceeds your expectations.

With our extensive experience and expertise in the manufacturing of HSS circular saw blades, we guarantee that we can deliver the highest quality products, at the most competitive prices. We are passionate about helping our clients increase their productivity, reduce their costs, and improve their bottom line.

If you are looking for a reliable, high-performance HSS circular saw blade manufacturer, you have come to the right place. Please contact us today to discuss how we can help take your business to the next level.

Thank you for choosing our products.

Sincerely yours,

The HSS Circular Saw Blade Team

Product Information

HSS saw blade is the abbreviation of high speed stee saw blade, which is often used for cutting steel, iron, stainless steel and other materials. It is the most commonly used cutting tool in the metal cutting industry. High-speed steel contains a large amount of carbon (C), tungsten (W), molybdenum (Mo), chromium (Cr), vanadium (V), etc.

Features

HSS saw blade is a saw blade composed of a large amount of carbon (C), tungsten (W), molybdenum (Mo), chromium (Cr), vanadium (V) and other elements. It has high hot hardness after heat treatment. Since the hardness of high-speed steel does not decrease significantly when the cutting temperature is as high as 600 ℃ or more, the cutting speed of the saw blade made of it can reach more than 60 meters per minute, and the high-speed steel saw blade is named after it.

Equipment

HSS Material

We have two kinds of HSS material, DMo5 and Co5, to meet our customers’ different requirements to saw blades.

HSS-DMo5

The material is called M2 high speed steel material in the AISI quality system standard and has a hardness of 64±1HRC, which is widely used for metal circular sawblades. It has good toughness and high wear resistance. HSS sawblades made by this kind of material are used for cutting metal workpieces with low tensile strength (≤800N/mm2) have good cutting performance, even in the field of cutting stainless steel materials.

HSS-Co5%

This kind of material has higher performance than HSS-DMo5, containing 5% cobalt. The hardness is 65±1HRC. It is called M35 material in the AISI quality system standard. HSS sawblades made by this material are often used for cutting the material that most difficult to cut, such as stainless steel or materials with high tensie strength (≥800N/mm2) and titanium alloy. The cobalt can significantly improve the cutting service life of the saw blades.

Our Products

We have developed and introduced several kinds of coating, and the following five popular coating are recommended to you.

| 1.TiN coating This coating can obtain low friction coefficient against metal workpiece. It increases saw blade surface hardness, heat resistance, tenacity, abrasion resistance and anti-adhesion to protect saw blade; It guarantee higher cutting speed and avoid of burr or scraps adhered to the blade tooth. Tt’s is a cost-effective coating. |

| 2.TiCN coating This coating is a multilayer coating with high hardness, low friction coefficient, better wear resistance and anti-adhesion, which can further improve the sawing speed and service life of the saw blade. It has a very significant effect in cutting highly viscous metals such as copper and stainless steel workpieces. |

| 3.TiAlN coating This coating is specifically used for cutting high alloy steels, stainless steels, very hard steels and abrasive materials such as cast iron, alloys of silicon-aluminium, brass, coper, nickel and titanium. It’s high hardness and low thermal conductivity allow the saw blade to be used for high speed cutting, even in conditions of poor lubrication or misting. |

| 4. AlTiN coating A new type of composite anti-wear coating with high hardness, high temperature resistance, good thermal hardness and strong adhesion. It is especially suitable for cutting of high alloy steel, stainless steel and other high strength material. It is also recommended for cutting thick-walled tubes and solid workpieces. Due to its high oxidation temperature and low thermal conductivity, it is especially suitable for dry cutting. |

| 5. VAPO coating VAPO helps to enhance the self-lubricating ability of the saw blade, maintain the toughness of the saw blade during operation, increas the service life of the saw blade, and is suitable for sawing low tensile strength materials. It’s affordable coating. |

Tooth Form & Geometry

| 1.Tooth form A is a normally used for jewellery and screw slotting with small tooth pitch. |

| 2.Tooth form AW is designed for machining work, such as slotting, with thin saw blade. |

| 3.Tooth form B is mostly used for light and very thin pipes and profiles, where it is not necessary to break the chip to evacuate the tooth groove. |

| 4.Tooth form BW is mainly used for cutting of pipes and profiles with walls. BW teeth is alternatively beveled. |

| 5.Tooth form C is used for cutting of solid material and thick pipe (>3mm). |

| 6.BR tooth form with chip breaker is used for tubes and profiles cutting, especially together with PVD coating because it guarantees an good surface finish and an higher number of cuts. |

1) T = Pitch 2) P = Tooth Height 3) B = Thickness 4) d = Gullet Diameter 5) α = Rake Angle 6) β = Relief Angle |  |

Sawblades Standard Sizes

FAQ

Q1: Can you also provide blank of HSS saw blade?

A: Yes, we can also provide HSS saw blade without tips ground.

Q2: How long is your delivery time?

A: For the new production, our general delivery time is 15-20 work days after receiving your order confirmation.

Hot Tags: hss circular saw blade, China hss circular saw blade manufacturers, suppliers, factory, Metal Frame Saw Blade For Grass, Kinkelder HSS DMo5 Circular Saw Blade, Diamond Saw Blade for Marble, 12 metal blade for miter saw, circular blade for aluminum, 8 inch metal cutting blade

You Might Also Like

Send Inquiry