How to improve the edge quality of a cut made by a copper saw blade?

Hey there! As a supplier of copper saw blades, I've had my fair share of experience dealing with all sorts of cutting issues. One of the most common problems customers face is getting that perfect edge quality when using a copper saw blade. In this blog, I'm gonna share some tips and tricks on how to improve the edge quality of a cut made by a copper saw blade.

Understanding the Basics

First things first, let's talk about what affects the edge quality of a cut. There are several factors at play here, including the type of saw blade, the material being cut, the cutting speed, and the feed rate.

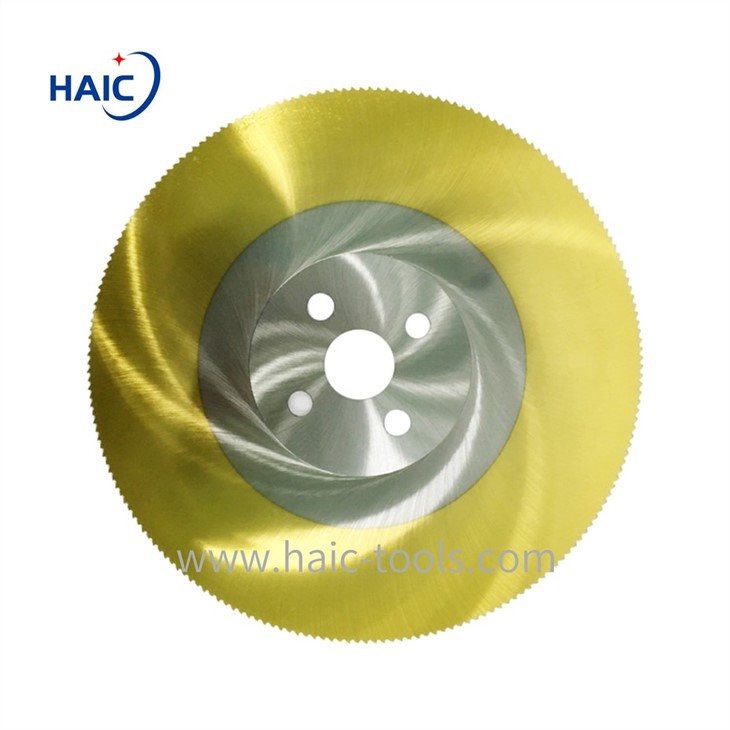

The type of saw blade is crucial. Different saw blades are designed for different materials and cutting applications. For copper, you want a saw blade that's specifically made for cutting metal. A HSS Circular Saw Blade is a great option. High-Speed Steel (HSS) blades are known for their durability and ability to maintain a sharp edge, which is essential for getting a clean cut on copper.

The material being cut also matters. Copper can vary in hardness and composition, so you need to choose the right blade and cutting parameters accordingly. Softer copper may require a different blade and cutting speed compared to harder copper alloys.

Choosing the Right Saw Blade

When it comes to choosing a saw blade for copper, there are a few things to keep in mind.

Tooth Design: The tooth design of the saw blade plays a big role in the edge quality. For copper, a blade with a fine tooth pitch is usually a good choice. Fine teeth help to reduce the amount of material removed per tooth, resulting in a smoother cut. Blades with a triple-chip grind or a alternate top bevel (ATB) tooth design are also popular for cutting copper as they provide a clean and precise cut.

Blade Thickness: The thickness of the saw blade can affect the edge quality as well. A thinner blade generally produces a cleaner cut because it removes less material and creates less heat. However, you need to make sure the blade is thick enough to withstand the cutting forces. An Ultra-thin Saw Blade for Aluminium can also be used for copper in some cases, as long as it's suitable for the cutting application.

Blade Diameter: The diameter of the saw blade should be appropriate for the size of the workpiece and the cutting machine. A larger diameter blade can cover more area and may be more efficient for cutting larger pieces of copper, but it also requires more power.

Setting the Right Cutting Parameters

Once you've chosen the right saw blade, it's time to set the cutting parameters correctly.

Cutting Speed: The cutting speed is the speed at which the saw blade rotates. For copper, a slower cutting speed is usually better to prevent overheating and to get a cleaner cut. You can refer to the manufacturer's recommendations for the optimal cutting speed based on the blade type and the thickness of the copper.

Feed Rate: The feed rate is the speed at which the workpiece is fed into the saw blade. A too-fast feed rate can cause the blade to bind or produce a rough cut, while a too-slow feed rate can lead to excessive heat buildup and dull the blade. You need to find the right balance for the best edge quality.

Maintaining the Saw Blade

Proper maintenance of the saw blade is essential for getting a good edge quality.

Sharpening: Regularly sharpening the saw blade is crucial. A dull blade will produce a rough cut and can also cause more wear and tear on the saw and the workpiece. You can either sharpen the blade yourself if you have the right tools and skills, or you can send it to a professional sharpening service.

Cleaning: Keeping the saw blade clean is also important. After each use, make sure to remove any debris or chips from the blade. You can use a brush or a cleaning solution to clean the blade. A clean blade will cut more efficiently and produce a better edge quality.

Using the Right Cutting Techniques

In addition to choosing the right saw blade and setting the correct cutting parameters, using the right cutting techniques can also improve the edge quality.

Support the Workpiece: Make sure the workpiece is properly supported during the cutting process. A unsupported or unstable workpiece can cause the blade to wander or produce a rough cut. You can use clamps or a workbench to support the workpiece.

Start the Cut Slowly: When starting the cut, start the saw blade slowly and gradually increase the speed. This helps to prevent the blade from binding or chipping.

Other Considerations

There are a few other things to keep in mind when cutting copper with a saw blade.

Lubrication: Using a lubricant can help to reduce friction and heat during the cutting process, which can improve the edge quality. You can use a cutting fluid or a lubricating spray specifically designed for metal cutting.

Safety First: Always follow the safety guidelines when using a saw blade. Wear appropriate safety gear, such as safety glasses, gloves, and ear protection. Make sure the saw is properly grounded and in good working condition.

Conclusion

Improving the edge quality of a cut made by a copper saw blade requires a combination of choosing the right saw blade, setting the correct cutting parameters, maintaining the blade, using the right cutting techniques, and considering other factors like lubrication and safety. By following these tips, you can achieve a cleaner, smoother, and more precise cut on copper.

If you're in the market for a high-quality copper saw blade or need more advice on improving the edge quality of your cuts, don't hesitate to reach out. We're here to help you find the best solution for your cutting needs. Whether you're a professional metalworker or a DIY enthusiast, we've got the right saw blade for you. Contact us for a quote or to discuss your specific requirements.

References

- Metal Cutting Handbook: A comprehensive guide to metal cutting processes and techniques.

- Saw Blade Manufacturer's Specifications: Information provided by the saw blade manufacturers regarding blade selection, cutting parameters, and maintenance.