What is Metal Cutting Saw Blade

Metal cutting saw blade to provide maximum performance when cutting ferrous and nonferrous metals. Compared to abrasive cutting wheels, metal cutting saw blade cut faster and more accurately. They also impart less heat and produce no hazardous dust.

Benefits of Metal Cutting Saw Blade

Wide range of sawing applications

Metal cutting saw blade consist of steel saw bodies with cermet and carbide-tipped teeth. The tips are then ground to match the application for which the blade is being used. Circular saws have a wide range of sawing applications such as: carbon steel, alloy steel, stainless steel, bearing steel, tool steel.

High cutting rates, low material losses

Longer life and faster cutting are the main reasons why a shop would switch to circular blades. Carbide-tipped blades start off sharper and remain sharp much longer than steel alternatives because of their great wear and heat resistance.

Less vibration, superb surface finish

Metal cutting saw blade generally create less vibration which will lower the noise level ultimately leading to a better surface finish of parts.

Increased productivity

If you are tired of wasting money on saw blades with short life spans, Metal cutting saw blade are well worth the investment. Generally, they stay sharper for a more extended period. Making that dreaded blade change happen less often allowing the saw to stay running and your operator to focus on more important tasks.

Metal cutting saw blade is a kind of important cutting tool in industrial manufacturing. It is widely used in automobile manufacturing, aerospace, medical instruments, gears and bearings, and almost all Metal cutting is inseparable from it.

According to different types of cutting materials, metal cutting saw blade can be divided into non-ferrous metal cutting saw blade, solid steel cutting saw blade, steel pipe cutting saw blade and stainless steel cutting saw blade, etc. According to the characteristics of the cutting tips, it can be divided into carbide tip cutting saw blade, cermet tip cutting saw blade and HSS cutting saw blade.

When using metal cutting saw blade, attention must be paid to cutting conditions, such as RPM speed, feeding speed and cooling conditions, otherwise the saw blade may not play a normal cutting performance. HAIC can not only provide high quality metal cutting saw blade, but also guide customers on how to cut correctly at any time.

Why Choose us

01

Advanced Equipment

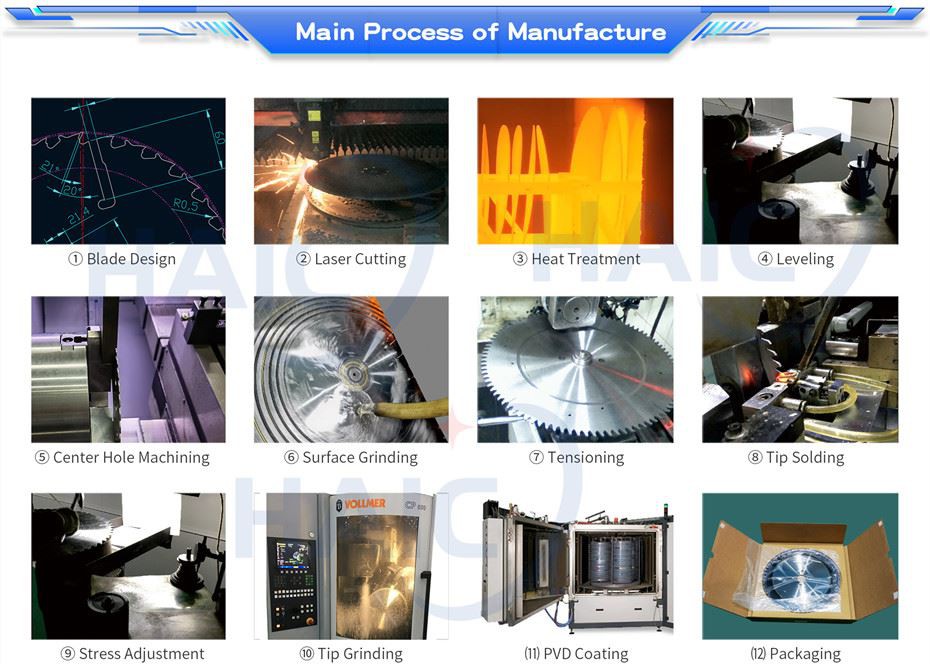

We have a complete set of imported production equipments from Europe and Japan, including laser cutting, heat treatment, tensioning, tip soldering, tip grinding and inspection, etc.

02

Rich Experience

With over 20 years of experience on cutting tools, fully familiar with various cutting tools, owning TCT circular saw blades, cold saw blades, HSS sawblades and PCD diamond saw blades to meet various requirement of materials being cut.

03

Production Market

Thanks to our customers' trust and support, up to now, besides more than 200 customers in China, we also have established stable business relations with more than 30 foreign dealers from Europe, South America and Asia.

04

Customer Service

We can help users at any time to analyze the problems they are facing and provide the best solution. We are also very pleased to cooperate with customers on product LOGO, packaging, transportation, samples and others.

How to Get The Most Out of Your Metal Cutting Saw Blade

Use the right blade

The key to getting the perfect cut is selecting the right blade. Different types of metal require different blades to get a cleaner cut and extend the life of your blade. Don't settle for anything less than the best.

Don't force the cut

It can be tempting to try and force the saw through the metal. But this will cause the saw to vibrate, resulting in a less precise cut. Instead, take your time and let the saw do the work.

Use the right speed

Different materials require different speeds. If you’re cutting aluminum, for instance, you should be running the saw at a slower speed than if you were cutting steel.

Keep your metal cutting saw blade clean

Keeping your metal cutting saw blade clean is key to its longevity and effectiveness. Make sure to regularly clean the metal cutting saw and replace any worn parts that may be causing it to run inefficiently.

●Cleaning

After each use, get rid of any debris or particles with a brush or compressed air.

●Storage

Store in a dry, clean place away from moisture or extreme temperatures to prevent corrosion.

●Sharpening

While it may be tempting to reuse or sharpen dull blades, it's usually better to replace them with new ones. Dull blades not only reduce cutting performance but also increase the danger of kickback or binding.

●Inspection

Check for cracks, chipped teeth, or bent segments before each use.

●Lubrication

Apply lubricant to reduce friction and ensure smooth cutting motion.

Considerations When Choosing A Metal Cutting Saw Blade

Type of tool

First, consider the type of tool that you're using with this blade. The four main types of saws are the table saw, radial-arm saw, chop saw, and miter saw. Some metal cutting saw blade are designed for a particular type of saw. It can be dangerous to use the wrong blade with your saw.

01

Type of cut

The type of cut that you'll want to use depends on the material you're working with as well as the type of project. A crosscut blade has more teeth and makes more individual cuts, so it moves through the wood smoother and at a slower rate. A ripping blade has fewer teeth and moves more quickly, so it removes more material at a faster rate.

02

Materials

Consider which materials you work with most frequently. Cutting into metal is different than cutting wood or plastic. Furthermore, cutting wood lumber is different than cutting wood panels. You want to consider the type of material and how you'll cut it. Materials include wood, metal, plastic, laminates, melamine, and non-ferrous metals.

03

Number of teeth

The number of teeth on your metal cutting saw blade will determine how it will cut a specific type of material. Blades with more teeth generally have a smoother cut, while blades with fewer teeth have a rougher cut but remove material faster.

04

Gullet size

The "gullet" is the space between each tooth. This is used to help remove extra material as it is cut away. Ripping blades cut at a faster rate and the tooth size is bigger. This means that the gullet needs to be deeper to handle the greater amount of material being removed.

05

Our Factory

Hangzhou Accurate International Co., Ltd. (HAIC for short) is a company specializing in the development, production and sales of circular saw blades. HAIC operates and manages in full accordance with Japan standards JIS B4805, Germany Din54 and D8033of circular sawblades, approved by SGS and ISO9001. With over 20 years of experience on cutting tools, HAIC is fully familiar with various cutting tools, owning TCT circular saw blades, cold saw blades, HSS sawblades and PCD diamond saw blades to meet various requirement of materials being cut.

Production Equipment

We always believe and insist that high precision and reliable equipment with good maintenance is the basis of producing quality products.

Our Certificate

We are a national high-tech enterprise and has passed the ISO9001 quality management system certification. In addition, due to our technical team's continuous innovation and supports from our Japanese technicians, we has obtained a total of 15 patents for inventions and utility models.

Frequently Asked Questions

Q: What is the meaning of metal cutting saw?

Q: How do I choose a metal cutting blade?

Q: What is the description of a saw blade?

Q: How are saw blades classified?

Q: What is the difference between metal and wood cutting blades?

Q: Can you cut metal with a regular saw?

Q: Do you need a special blade to cut metal?

Q: What saw blade makes the smoothest cut?

Q: Is more teeth on a saw blade better for metal?

Q: How do you tell if a saw blade is meant for metal?

Q: Should I oil my saw blade?

Q: What is a metal cutting blade used for?

Q: What type of blade is used to cut metal?

Q: Can saw blades cut metal?

Q: What is a non ferrous metal cutting blade?

Q: Can you put a metal cutting blade on a chop saw?

Q: Can I put a metal cutting blade on my circular saw?

Q: What is a metal cutting saw called?

Q: How do I know if my saw blade is bad?

Q: Which saw blades make the smoothest cut?

We're professional metal cutting saw blade manufacturers and suppliers in China, specialized in providing high quality customized products. We warmly welcome you to wholesale high-grade metal cutting saw blade at competitive price from our factory.

Frame Precision TCT Saw Blade, bimetallic bandsaw blade, steel rod cutting blade